Pratteln, Switzerland, September 2022. At K2022, BUSS AG will be explaining the possibilities of its digitalized machine monitoring project, which is designed to extend machine service life and uninterrupted production runs, identify maintenance needs at an early stage and avoid unforeseen downtime. BUSS will also be presenting its wide-ranging expertise as a partner in plant engineering for all aspects of compounding. Another focus will be the addition of a laboratory version to the versatile COMPEO co-kneader series.

Making maintenance requirements plannable

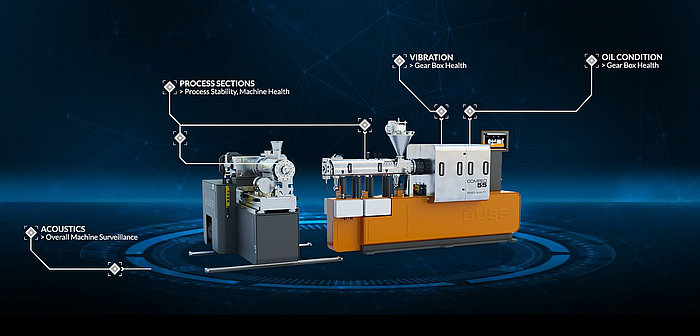

Condition-based monitoring, the ongoing acquisition of parameters indicating the status of individual components and entire assemblies in a machine or plant system, is the foundation of the new SenseHUB service from BUSS. Sensors for acquiring process section, vibration data or other metrics elucidate the condition of the manufacturing system at critical points on machines such as kneaders, discharge and dosing units, pelletizers, heaters and coolers. Following data analysis, the user can call up the visualized results in the SenseHUB dashboard on the BUSS service portal. This BUSS service carries out monitoring, evaluation, and planning of any necessary repair work in direct consultation with the customer. Not limited to the compounding unit of the BUSS co-kneader, the SenseHUB service will be extended to additional sensor data for the evaluation of the machine health, ensuring maximized production uptime.

Focus on complete systems

Where required, BUSS can supply greater complexity in the form of complete systems for various applications and is increasingly designing and implementing custom applications as a one-stop shop supplier working hand in hand with selected manufacturers. Depending on the scope of the project, such systems may include not only material dosing, kneading, discharging and pelletizing but also a variety of other components, such as filters, coolers, materials handling systems, quality control systems, clean room design and more.

Co-kneader even more versatile

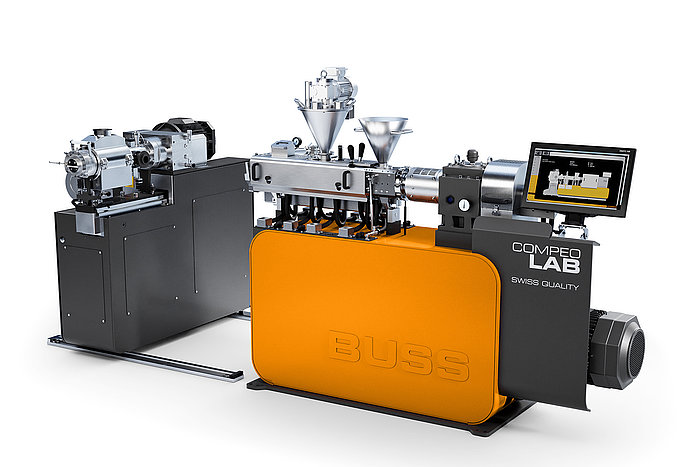

The cornerstone of any system supplied by BUSS is a COMPEO series co-kneader which is designed to incorporate high levels of additives gently and thoroughly into base materials. The modular machine design is so flexible that a specially configured compounding line is available for any application at any temperature up to 400°C and for all plastics, ranging from thermally sensitive thermosets to demanding engineering thermoplastics.

The latest addition to the family of the series of five production units with throughput levels, depending on application, of 100 to over 12,000 kg/h is the new compact, user-friendly COMPEO LAB laboratory compounder for throughputs of 50 to 100 kg/h for development, process optimization and small production campaigns. It offers all the advantages of the large COMPEO co-kneaders, including the combination of two-, three- and four-flight screw elements, and provides precise and reliable scale-up of process parameters to production conditions.

BUSS is an international market leader in compounding systems for demanding applications. As the originator of co-kneader technology, BUSS can offer unique compounding solutions that set the standard for heat or shear critical applications in the plastics, aluminum, chemicals and food processing industries. BUSS's core expertise is in providing customized and application-specific solutions for advanced compounding tasks to meet stringent process technology and product quality requirements and ever greater market demand for sophisticated technology. “Swiss quality” explains why BUSS compounding systems perform so well, are a reliable investment and have made the company a leading supplier of advanced compounding technology.

Further information:

Dr. Krischan Jeltsch

BUSS AG, Hohenrainstrasse 10, CH-4133 Pratteln, Switzerland

Tel. +41 (0)61 825 63 06,

Email: krischan.jeltsch(at)BUSScorp.com

www.BUSScorp.com

Editorial contact and voucher copies:

Dr.-Ing. Jörg Wolters

KONSENS Public Relations GmbH & Co. KG

Im Kühlen Grund 10, D-64823 Gross-Umstadt, Germany

Tel. +49 (0)60 78 93 63 13

Email: joerg.wolters(at)konsens.de

Efficient

Efficient Trade Media Relations

Press Information

BUSS at K2022: Pioneer in Digitalization, Focus on System Engineering, COMPEO Now Even More Versatile

[

Buss AG

]

Continuous, sensor-assisted monitoring of machine status and cloud-based data analysis are the foundation of the new SenseHUB service from BUSS that helps customers extend machine runtime and avoid unplanned downtime. © BUSS