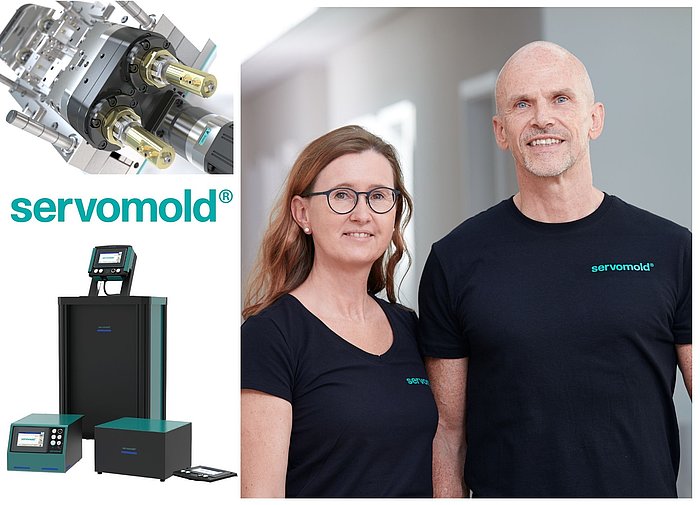

Erbach, February 2022 - On 1 February 2022, the former i-mold GmbH & Co. KG changed its name to Servomold GmbH & Co. KG. The managing directors Bianca and Thomas Meister thus emphasize the focus on application-specific components and integrated system solutions for the automation of injection mold tools. The large number of over 600 plug-and-play controllers sold worldwide as part of the Servomold product line for the servo-electric realisation of rotary and linear movements exemplifies the success of this sophisticated technology.

Started in 1998 as a design service provider, the development and patenting of tunnel gate inserts followed just one year later. In 2011, Thomas Meister founded the Servomold division, whose name the company has now taken over. "As a consultant, designer and supplier, we combine over 20 years of corporate experience in all aspects of injection mold tools automation," says Meister. "Our technologies offer countless possibilities to realize rotational and linear movements with the highest process and mold safety, while at the same time enabling significant energy savings compared to hydraulic and pneumatic systems." The business with tunnel gate inserts will be continued by the previous co-managing director Andy Walter in a separate company.

Servomold manufactures the individually designed systems up to the complete unscrewing half in-house and supplements special designs with modular components such as thread core systems, indexing plate drives, unscrewing units, drive units and linear actuators. In the application-specific realisation of corresponding complete solutions, the company includes - beyond the tool - the entire process chain. Commissioning worldwide on site as well as remote services complete the offer.

Thomas Meister continues: "Servo components create ideal conditions for the realisation of minimum cycle times, maximum availability as well as comprehensive process control and verifiability. Especially when using all-electric injection moulding machines, they are the ideal complement for achieving clean operating conditions. We look forward to perfecting and further developing our proven performance under the Servomold company name. For example, we will soon be able to present a completely newly developed control system, further strengthening the basis for successful cooperation with our customers."

Servomold GmbH & Co. KG, headquartered in Erbach, Germany, is an experienced partner to the toolmaking industry for plastic injection moulding. The company name stands for a growing number of standardised and individual solutions for the servo-electric and thus clean, space-saving realization of rotational and linear movements in injection mold tools. Applications range from individual threads in technical plastic parts to linear slide and core pull movements to multi-cavity closure cap molds.

Further information:

Thomas Meister, Servomold GmbH & Co. KG

Gewerbepark Gräsig 72, D-64711 Erbach, Germany

Phone: +49(0) 60 62/80 933-0; info(at)servomold.com, www.servomold.com

Editorial contact and please send voucher copies to:

Dr.-Ing. Jörg Wolters, KONSENS Public Relations GmbH & Co. KG

Im Kühlen Grund 10, D-64823 Groß-Umstadt, Germany

Phone: +49(0) 60 78/93 63-13, mail(at)konsens.de

Efficient

Efficient