Königsbrunn/Germany, September 2022 - Flakes obtained from plastic waste by grinding can be processed directly in the injection molding process if any foreign substances are thoroughly removed from the melt. The associated technology was developed by injection molding machine manufacturer ENGEL, which chose a high-performance melt filter from Ettlinger, a manufacturer belonging to the Maag Group. This continuously ensures the required purity and thus enables consistent product quality at a high level of production efficiency. The elimination of a separate pelletizing step conserves material and reduces energy requirements and CO2 emissions, contributing to even greater sustainability in the recycling of plastics.

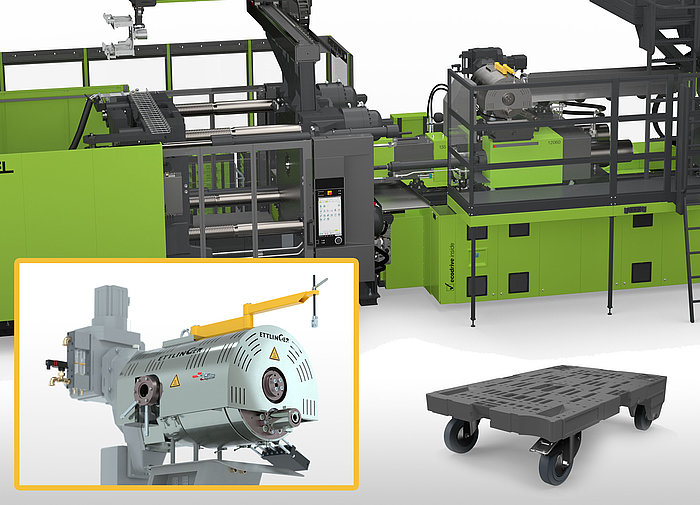

The heart of the innovative, two-stage technology, which ENGEL will be presenting live for the first time at the K2022 trade fair, is a modular injection molding machine from the duo series, designed for the two-stage process. The ERF350 melt filter from Ettlinger, like the additional degassing unit, is positioned between the plasticizing unit and the separate injection unit. ENGEL decided to integrate this filter because of its ability to continuously and reliably separate solid and elastomeric contaminants from the plastic melt at contamination levels of up to 16%. It operates on a self-cleaning basis, using a rotating, perforated drum, through which there is a flow of melt from the outside to the inside. As it rotates, a scraper removes the contaminants that are held back on the surface and diverts them to the discharge system. This grants the user fully automatic and uninterrupted long-term operation with excellent mixing and homogenization of the melt.

Visitors to K2022 can experience the use of the ERF350 live at the ENGEL booth in the Circular Economy Forum in the outdoor area between Halls 11 and 16. A mixture of post-industrial polyolefins is used there to produce rollable logistics load carriers known as dolly pallets - large-volume molded parts of the kind often made from recycled materials.

About ENGEL:

ENGEL is one of the global leaders in the manufacture of plastics processing machines. Today, the ENGEL Group offers a full range of technology modules for plastics processing as a single source supplier: injection molding machines for thermoplastics and elastomers together with automation, with individual components also being competitive and successful in the market. With nine production plants in Europe, North America and Asia (China and Korea), and subsidiaries and representatives in more than 85 countries, ENGEL offers its customers the excellent global support they need to compete and succeed with new technologies and leading-edge production systems.

Information about the MAAG Group

The MAAG Group is a broadly diversified global solution provider with integrated and customizable systems in process technology for the polymer, chemical, petrochemical, pharmaceutical and food industries. Its Pump & Filtration Systems, Pelletizing & Pulverizing Systems and Recycling Systems consolidate the many years of experience and in-depth know-how of the AUTOMATIK, ETTLINGER, GALA, MAAG, REDUCTION and SCHEER product brands Today, the MAAG Group employs over 1,000 people at production sites in Switzerland, Germany, Italy, the USA, and China. Additional sales and service centers in France, Singapore, Taiwan, Malaysia, India, Thailand and Brazil ensure close attention to customers’ needs. You will find more information at www.maag.com.

MAAG Group is a business unit of Dover Fluids, a segment of Dover Corporation.

About ETTLINGER

ETTLINGER is the product brand for recycling systems within the MAAG Group. The focus is on high-performance melt filters for the recycling of plastics. Injection molding machines round off the portfolio. The company was founded in 1983 and has its development and manufacturing headquarters in Königsbrunn near Augsburg, Germany. ETTLINGER has been part of the MAAG Group since 2018.

More information on Ettlinger

Karsten Bräunig, Sales Manager

Ettlinger Kunststoffmaschinen GmbH, Messerschmittring 49, 86343 Königsbrunn, Germany

Tel.: +49 8231 34908 -12, Email: karsten.braeunig(at)maag.com

www.maag.com

Editorial contact and specimen copies:

Dr. Jörg Wolters, Konsens PR GmbH & Co. KG

Im Kühlen Grund 10, 64823 Groß-Umstadt, Germany

Tel.: +49 (0) 60 78 / 93 63 - 13, Email: joerg.wolters(at)konsens.de

Efficient

Efficient Trade Media Relations

Press Information

High-performance melt filter enables sustainable flake processing in direct injection molding

[

Maag Ettlinger

]

[

Maag Ettlinger

]