San Polo di Piave/Italy, November 2022 – Oerlikon HRSflow has developed special hot runner solutions for PCR compounds. Their application possibilities are demonstrated by two examples realized in practice – a fruit crate and a garbage can for composting organic household waste. With these environmentally friendly projects, which were implemented together with various partners, the company underlines its commitment to the circular economy.

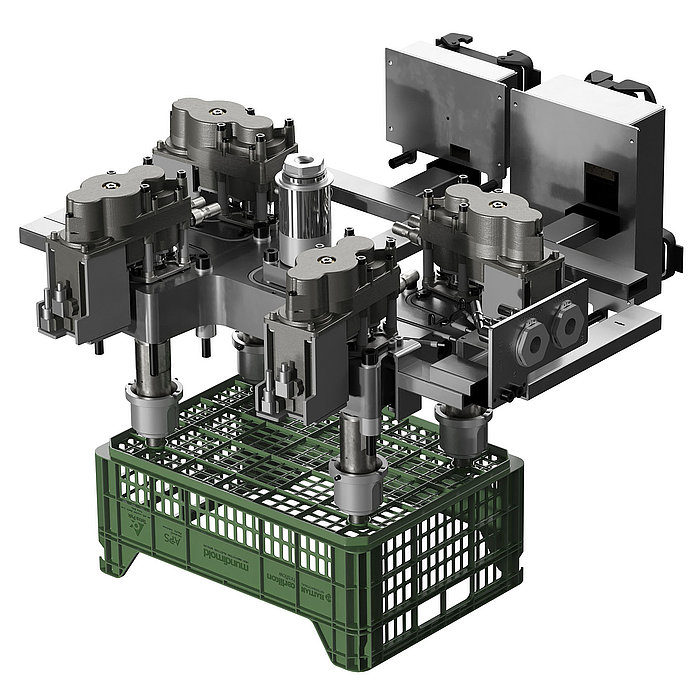

For the production of the fruit crates, Mundimold processes an optimized PE compound from APS, Valencia/Spain, which is obtained from the recycling of Tetra Pak® card-board packaging. In the production of this demanding part, which was demonstrated at K 2022 on a servo-hydraulic Haitian Jupiter with two-platen technology and 4,500 kN clamping force, a servo-controlled FLEXflow valve gate hot runner system with four drops contributes to the high repeatability of the process. Optimum gate quality is ensured by the new, patent pending TTC cooling bushing from Oerlikon HRSflow, which prevents needle sticking even with short cycle times. The low energy consumption of the FLEXflow system supports energy-efficient production. Project partners were Haitian, Mundimold, Tetra Pak, APS and Oerlikon HRSflow. The production process is explained clearly in this video: Eco-friendly Fruit Box: Maximum Precision Combined with Sustainability.

Another example is the Bokashi Organko Essential, an airtight sealable bucket for home composting. The 775 g part with 2.5 mm wall thickness is produced of PCR polymers using an Oerlikon HRSflow two-drops hot runner system. This is optimized for frequent color changes and designed so that remaining contaminating particles in the recyclate do not cause damage, streaks or flow marks that could affect the aesthetic and functional result (courtesy of PLASTIKA SKAZA).

About Oerlikon HRSflow

Oerlikon HRSflow (www.hrsflow.com), part of the Swiss technology group Oerlikon and its Polymer Processing Solutions Division, is based in San Polo di Piave/Italy and specializes in the development and production of advanced and innovative hot runner systems for the injection molding industry. The business line employs about 1,000 people and is present in all major global markets. Oerlikon HRSflow manufactures hot runner systems at its European headquarters in San Polo di Piave, Italy, its Asian headquarters in Hangzhou, China, and its Byron Center facility near Grand Rapids, MI, USA.

For further information, please contact:

Chiara Montagner

Marketing & Communication Manager

Oerlikon HRSflow

Tel: +39 0422 750 127

Fax: +39 0422 750 303

chiara.montagner(at)oerlikon.com

www.oerlikon.com/hrsflow

Erica Gaggiato

Marketing & Communication Specialist

Oerlikon HRSflow

Tel: +39 0422 750 120

Fax: +39 0422 750 303

erica.gaggiato(at)oerlikon.com

www.oerlikon.com/hrsflow

Editorial contact and please send voucher copies to:

Dr.-Ing. Jörg Wolters

Konsens PR GmbH & Co. KG

Im Kühlen Grund 10, D-64823 Groß-Umstadt, Germany

Tel: +49 6078 9363 13mail(at)konsens.de

Efficient

Efficient