Heilbronn / Germany, December 2022 – BRUGGOLEN® TP-H2217 belongs to a new class of electrically neutral thermostabilisers from Brüggemann. Specially developed for reinforced and unreinforced aliphatic polyamides with metal- and halogen-free flame retardancy requirements, it ideally meets the needs of electrical and electronic applications, including those of e-mobility. Despite its high efficiency it neither has a corrosive effect on metallic components such as overmoulded sensors, nor does it influence the electrical properties of the polymer it is protecting in any significant way.

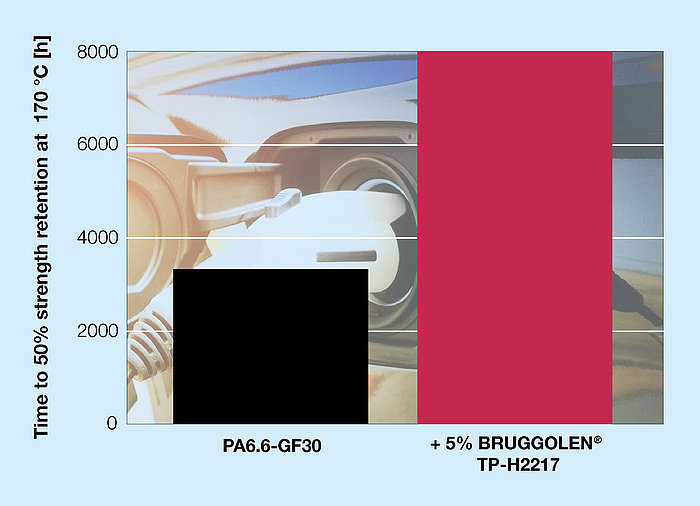

The high efficiency of long-term stabilisation is demonstrated by the example of a PA6.6-GF30. After 8,000 h of heat storage at 170°C, the tensile strength values are still over 50%.

A key requirement of any additives used in e-mobility applications is that the flame retardancy properties of those applications are not harmed. BRUGGOLEN® TP-H2217 is neutral in this respect as is Brüggemann’s new flow enhancer, BRUGGOLEN® TP-P2201, which is used to process glass-fibre reinforced polyamides into thin-walled and complex components with long flow paths.

Dr Kristina Frädrich, Product Manager at Brüggemann, comments: "With BRUGGOLEN® TP-H2217, compounders can for the first time produce polyamide materials that combine a UL94 V-0 classification, electrical neutrality as well as permanent heat resistance at elevated temperatures, and are thus specially tailored to the increased requirements of e-mobility. With this combination, which neither phenol- nor amine-based grades can offer, Brüggemann raises the bar for thermo-stabilisers by a considerable margin."

BRUGGOLEN® TP-H2217 is available as an easy-to-process masterbatch in granular form, with a level of 3% proving sufficient for many applications in laboratory trials.

L. Brüggemann GmbH & Co. KG, an independent family-owned company headquartered in Heilbronn (Germany), offers tailor-made solutions in the areas of polymer additives, industrial chemicals and ethanol. Brüggemann specializes in the development and production of high-performance additives for engineering thermoplastics with a focus on polyamides, as well as zinc derivatives and sulfur-based reducing agents. Customers have come to value the company's flexibility and innovative product solutions, while subsidiaries in the USA and Hong Kong emphasize its international outlook. The cornerstones of corporate policy are in-house research and development activities, a consistent focus on customer requirements, and major investments in know-how and production plants. Founded in Heilbronn in 1868, Brüggemann now supplies customers in more than 60 countries.

Further information:

Dr. Klaus Bergmann, Business Unit Manager Polymer Additives

L. Brüggemann GmbH & Co. KG, Salzstraße 131, 74076 Heilbronn, Germany

Phone: +49 (0) 71 31 / 15 75 – 235, email: klaus.bergmann(at)brueggemann.com

Editorial contact and please send voucher copies to:

Dr.-Ing. Jörg Wolters, Konsens PR GmbH & Co. KG,

Im Kühlen Grund 10, 64823 Groß-Umstadt, Germany

Phone: +49 (0) 60 78 / 93 63 - 13, email: joerg.wolters(at)konsens.de

Efficient

Efficient Trade Media Relations

Press Information

New copper and halogen-free long-term heat stabilisers tailored for applications in E&E and e-mobility

[

L. Brüggemann GmbH & Co. KG

]