AGC Chemicals Europe (www.agcce.com) is a leading manufacturer of fluoroplastics and the world's largest producer of ETFE (ethylene tetrafluoroethylene copolymer) and ion exchange membranes. At K 2022, they will be presenting new developments in its Fluon+™ functionalised fluoropolymer range. Located in Hall 7a C12, AGC is also celebrating 50 years since the launch of Fluon® ETFE, and will also be promoting their range of high-performance AFLAS® FFKM elastomers.

Functionalised PTFE additives for improved dispersion in base polymers

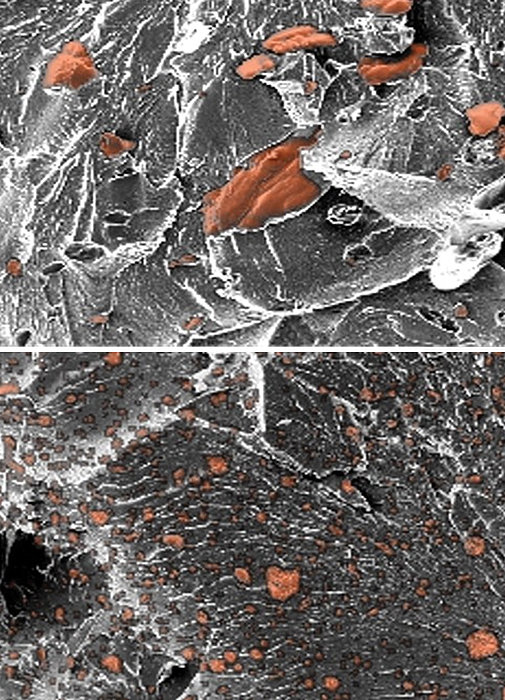

Functionalised PTFE additives are new to AGC’s range of Fluon+™ MODIFIERS and are aimed at modifying the tribology of plastic compounds. Thanks to their optimised compatibility with common matrix materials such as polyphthalamide (PPA) or polyoxymethylene (POM), more uniform dispersal in the polymer matrix is achievable compared to conventional PTFE micropowders. As a result, PTFE particles are distributed evenly throughout the finished component, and available on its surface so that the usual wear-in period is removed.

Tests on a PPA modified with Fluon+™ MODIFIERS PTFE showed a reduction in wear of approximately 70% compared to a compound with a conventional PTFE additive, and a 30% reduction in friction losses. In addition, functionalised PTFE did not measurably affect the mechanical properties of the base polymer.

AGC's Fluon+™ MODIFIERS family of functionalised PTFE additives are now available for sampling upon request.

Fluon+™ is a family of functionalised fluoropolymers modified with reactive groups during polymerisation using an innovative technology developed by AGC. The range includes Fluon+™ MPC melt-processable fluoropolymers, Fluon+™ ADHESIVE adhesion promoters, Fluon+™ COMPOSITES compatibility promoters for novel composite structures, Fluon+™ MODIFIERS additives and Fluon+™ mPLASTICS processing aids.

AFLAS® FFKM - outstanding performance in the most demanding conditions

Under the AFLAS® brand, AGC offers fluoroelastomers for applications that require the highest level of reliability coupled with the elastomeric properties of synthetic rubber.

New to the range are perfluorinated rubbers (FFKM), which not only combine maximum chemical resistance with exceptional sealing performance, but also withstand extremely high operating temperatures. They are therefore ideal as O-rings and seals for critical applications under the most demanding conditions in the chemical industry, the oil and gas industry and semiconductor production. The range includes:

- AFLAS® PM-1100: basic type for continuous service temperatures of 230 °C, briefly up to 250 °C, for general applications.

- AFLAS® PM-3000: universal grade for continuous service temperatures of 250 °C, short-term up to 270 °C, high compression set, helps to extend maintenance intervals.

- AFLAS® PM-3500: free from fillers, no particle release. Specially developed for processes that demand the highest level of purity. High Shore A hardness of 70 and plasma resistant, it is ideal for etching processes in semiconductor production.

In addition, AGC's AFLAS® family includes a range of FEPM (tetrafluoroethylene-propylene) grades for applications requiring excellent resistance to elevated temperatures (up to 200 °C, briefly above), chemicals, oils, acids, bases, solvents, ozone, and steam.

50 years of Fluon® ETFE, 50 years of continuous development

AGC commercialised Fluon® ETFE in 1972 and has continued to develop its offering over the past 50 years. Today, the company is the world's largest producer of these high-performance fluoropolymers. ETFE is used in a wide variety of applications, e.g., hoses and pipes, chemical tank linings, wire and cable sheathing, valve coatings and as films for façade and roof constructions in architecture. Their special properties include good mechanical strength, cut-through resistance, excellent thermal stability, resistance to aggressive media as well as UV and weather resistance.

In the automotive industry, cable sheaths made from Fluon® ETFE are a more efficient alternative to conventionally used materials such as polyethylene (PE) or polypropylene (PP). Thanks to their thermal stability, chemical resistance, and flexibility, they can help extend the life of under bonnet cables for hybrid or electric vehicles.

Architects and planners worldwide use Fluon® ETFE FILM in numerous buildings as an alternative to glass for facade and roof constructions. Examples include the roof of SoFi Stadium in Inglewood, California, home of the Los Angeles Rams and the Los Angeles Chargers of the National Football League, and the National Aquatics Centre in Beijing, China, which was converted into an 'Ice Cube' for the 2022 Winter Olympics. Despite being significantly lighter than glass, ETFE foils are tear and scratch resistant even under the most demanding operating conditions. They are also resistant to UV radiation and weather. In addition, they can make a valuable contribution to the fire safety of buildings as their melting point is 260 °C.

For more information on AGC's portfolio: www.agcce.com

About AGC and AGC Chemicals

AGC is a leading global manufacturer of glass, chemicals, electronic materials and ceramics, and the world's largest producer of flat and automotive glass, ETFE fluoroplastic and ion exchange membranes. AGC has its headquarters in Tokyo/Japan, employs around 53,200 people worldwide and is one of the largest companies in the Mitsubishi group. It is listed on the Tokyo Stock Exchange and was named by Thomson Reuters as one of the Top 100 Global Innovators. Its products are used in the automotive and aerospace industries, architecture, sports arenas, greenhouses, refrigeration and air conditioning systems, pharmaceutical and agrochemical applications as well as in the extraction of minerals, oil and gas.

Fluon®, the leading brand for ETFE, is widely used in the automotive industry due to its light weight. The Fluon® brand also includes ETFE foils, PTFE and PFA. Other well-known AGC Chemicals brands are AFLAS® (fluoroelastomers), AMOLEA™ (refrigerant gases and solvents), AsahiGuard® (water and oil repellents), CYTOP™ (amorphous fluoroplastics), F-CLEAN™ (ETFE films for greenhouses), FORBLUE™ FLEMION (ion exchange membranes), LUMIFLON™ (FEVE, soluble additives for paints) & PREMINOL™ (polyols for polyurethanes).

Contact AGC Chemicals Europe:

Karolina Zielony

E-mail: agcce.marketing@agc.com

Phone: + 44 (0) 1253 209-560

Editorial contact and voucher copies:

Konsens PR GmbH & Co. KG

Barbara Welsch

E-mail: mail@konsens.de

Phone: +49 (0) 6078 936314

Efficient

Efficient