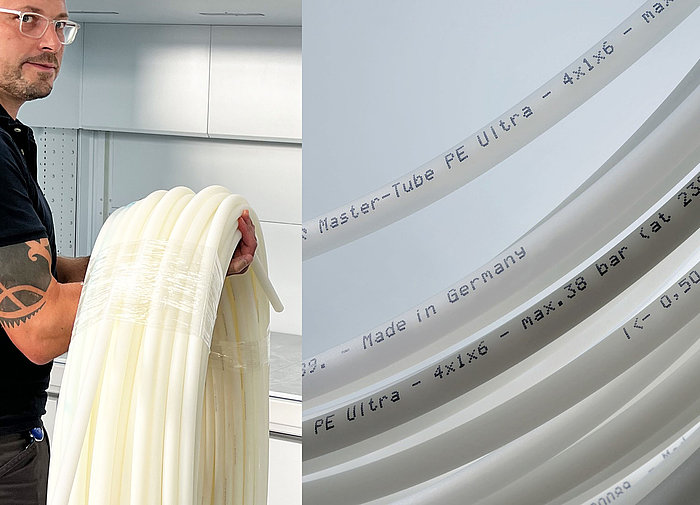

Meerbusch, Germany, October 2022 – By adding Lubmer™ L5000 from Mitsui Chemicals to its portfolio, the distributor DREYPLAS now has an ultra-high molecular weight grade of polyethylene (UHMW-PE) in pellet form which can be processed like conventional thermoplastics, so also suiting it to the extrusion of pipes, hoses and profiles. One of the first adopters is Novoplast Schlauchtechnik in Halberstadt, Germany. Working hand in hand with DREYPLAS, Novoplast has developed a now patented process for manufacturing hoses from Lubmer L5000 as a continuous reel product. Known by the product name PE Ultra, these hoses are used in industrial, medical and other applications. Lubmer LS4140, a blend based on chemically coupled PA6 and UHMW-PE components, is suitable for similar applications requiring elevated temperature resistance.

Extruded products made from these melt-processable Lubmer grades combine flexibility and impact strength at low temperatures down to –200°C, elevated chemical resistance and very good tribological properties on a par with conventional UHMW-PE, which can only be machined, with LS4140 providing higher rigidity, strength and abrasion resistance. Both grades meet REACH requirements, are suitable for food contact to EU 1935/2004 or EU 10/2011 and are FDA compliant. This means they can fill the gap between polyolefins and fluoropolymers, for example polytetrafluoroethylene (PTFE), and can in specific applications even provide a cost-effective replacement for fluoropolymers, which are currently in short supply on the market.

In addition to the highly abrasion-resistant extrusion grades Lubmer L5000 and LS4140, DREYPLAS also distributes not only high-flow injection molding grades, including the L3000 and somewhat higher viscosity L4000 grades, but also the additive LY1040, which imparts still higher abrasion resistance combined with a reduced coefficient of friction to many engineering polymers.

The opaque, light intrinsic color of all grades facilitates the use of color masterbatches, which, like other functional additives, can be incorporated using conventional dosing systems. Thanks to being recyclable as polyolefins and the possibility of remelting production scrap and returning it to the production cycle, Lubmer extrusion and injection molding grades provide environmentally responsible, sustainable solutions.

DREYPLAS is a distributor founded in 2010 and based in Meerbusch, Germany. Its portfolio covers high-performance additives and polymers as well as adhesive raw materials, mainly from major Asian manufacturers, and focuses on technically high-quality alternatives to established products. Its customers are polymer manufacturers, compounders, coating producers and plastics processors in Europe. The US subsidiary DREYTEK Inc., New Jersey, founded in 2015, markets these products in Mexico, the US and Canada. With this subsidiary and a partner in Asia, DREYPLAS offers global technical support in development and processing. All products are marketed globally and stored and invoiced locally.

DREYCHEM GmbH, Moormerland, Germany, which also belongs to the DREYPLAS group, develops, produces and markets highly effective cleaning granules for injection molding and extrusion, including for elevated temperatures. EFP GmbH, Meerbusch, Germany, another member the group, markets specialty films, e.g. of polycarbonate and PMMA, as well as flame-retardant film in Europe and the US. EFP is currently the world’s only supplier of extruded UHMW-PE films.

Further information:

Norbert Hodrius, DREYPLAS GmbH, Meerbuscher Str. 64-78 Haus 6A, D-40670 Meerbusch

Tel. +49-2159-815 31-11, Fax +49-2159-815 31-29, hodrius(at)dreyplas.com

Editorial contact and voucher copies:

Dr. Jörg Wolters, Konsens PR GmbH & Co. KG, Im Kühlen Grund 10, D-64823 Groß-Umstadt

Tel: +49 (0) 60 78/93 63-0, E-Mail: joerg.wolters(at)konsens.de

Efficient

Efficient Trade Media Relations

Press Information

Thermoplastic UHMW-PE for pipe, hose and profile extrusion

[

DREYPLAS GmbH

]

[

DREYPLAS GmbH

]